Raw Material System Retrofit and Modernization

Cement factories are always facing many ordinary situations of which are decreased production,lower productitivity, insufficient quality of product , high cost of operation, uncontrollable emission, visible consumption of power and rising cost of inventory for spare parts. if you are involved in one of above, you need to remedy, and you are strongly recommended to audit your production lines and start to retrofit and modernize your facilities. Perfect are focusing on optimization for your factory.

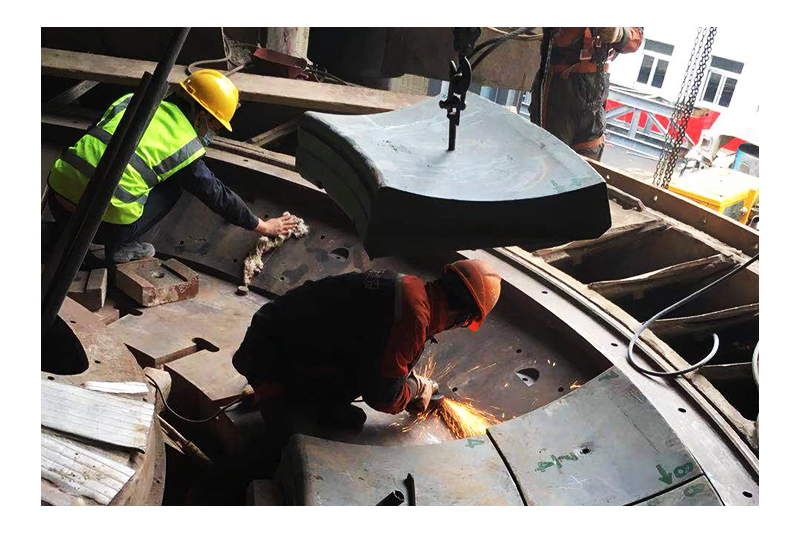

Furnace System Upgrade Project

With the development of economy and the digitalization of the science and technology, the infrastructure and skyscraps are symbols of urbanisation in a lot of developed and developing countries accompanying demands of cement industry are booming with.

Increasing the capacity or productivity is a trend to choose for many cement manufacturer. to reduce the cost and add value,to save energy and reduce the emission ,is a way to sustainable development approach.

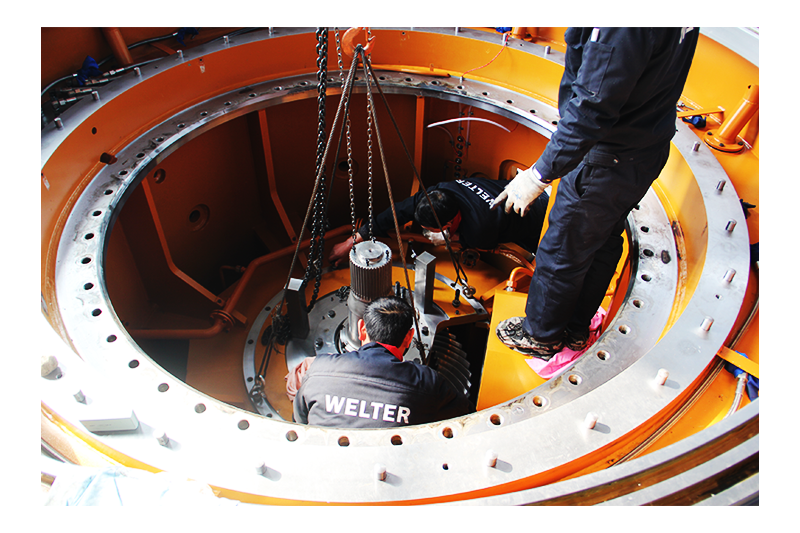

Grinding System Upgrading

Investment expense is always based on the expected return, and the capacity increasing is depending on the site specific condition and product line environment. In fact, different factory owns different working situations. our expertise will analyse and recommend how your operation and project can be modified and retrofited or even replaced with new advanced equipment.

some of these situations can be fixed flexible in various approaches, upgrade the raw mills grinding system, increase the ability of air separator, reduce the attrition, or even change the channels or chutes which are the effective ways to influence the productivity.