5% production improved! ATOX vertical mill air saparator replacement efficiency.

Publishdate:2021-03-10 Views:1217

摘要

summary

we did a project for ATOX50 raw mill retrofit and modernization with replacing a new rotor and other spareparts related in December 2020,which was so succussful and made the mill run stably.

People in project: 5 people

period under construction:7 days.

The cunstruction crane: 75 tons.

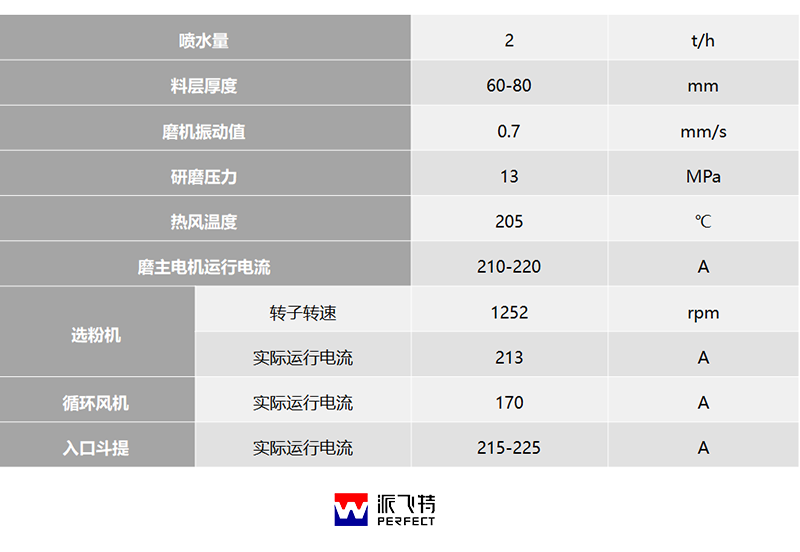

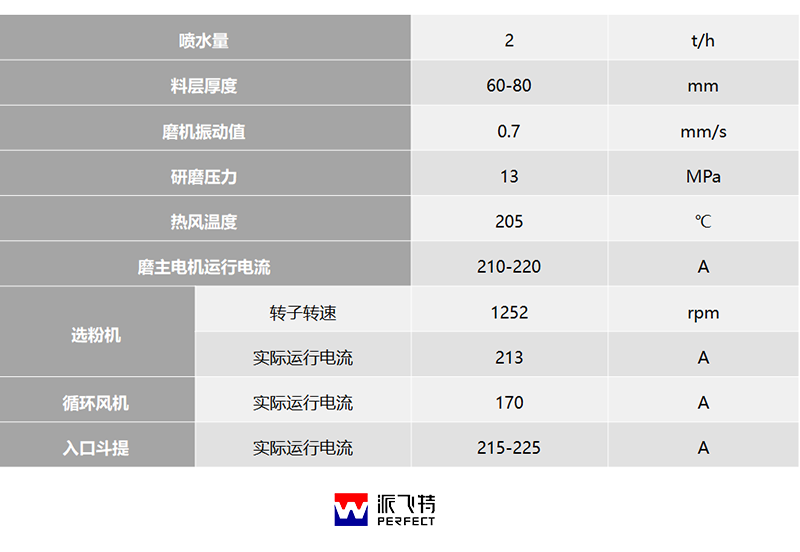

更换前中控操作画面

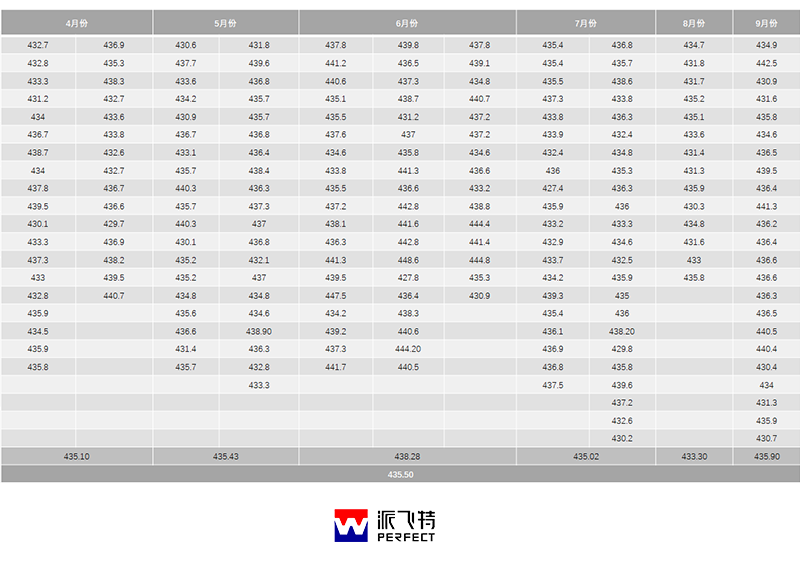

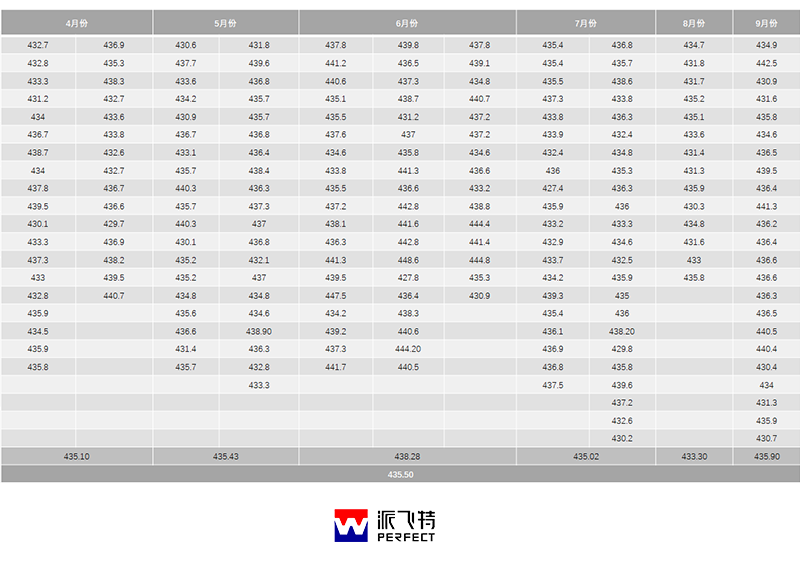

The data of productivity in April to September 2020.

1,Replace the bucket to reduce the resistant and improve the efficency.

2、Replace the assembly of guide vanes.

3,Replace the rotor of new model which is upgraded and designed with newshaped vanes that changed the angle of airflow and reduced the resistant to improve the capacity and efficiency.

4、Change the seal of rotor.

It is improved with 5% productivity after the replacement from 435T/H to 455-460T/H

撰稿人:工程技术部 吴汇生

摘要

summary

we did a project for ATOX50 raw mill retrofit and modernization with replacing a new rotor and other spareparts related in December 2020,which was so succussful and made the mill run stably.

People in project: 5 people

period under construction:7 days.

The cunstruction crane: 75 tons.

更换前中控操作画面

The data of productivity in April to September 2020.

1,Replace the bucket to reduce the resistant and improve the efficency.

2、Replace the assembly of guide vanes.

3,Replace the rotor of new model which is upgraded and designed with newshaped vanes that changed the angle of airflow and reduced the resistant to improve the capacity and efficiency.

4、Change the seal of rotor.

It is improved with 5% productivity after the replacement from 435T/H to 455-460T/H

撰稿人:工程技术部 吴汇生