The Efficiency of Rotor Replacement for ATOX50

Publishdate:2021-07-19 Views:1054

We replaced the rotor of ATOX50 raw mill and other related accessories which were upgraded and optimized , forced the capacity of productivity arising as 5% more and working in good condition.

1, The before status:

|

item |

Percentages |

||||

|

limestone |

Sandstone |

bauxite |

Sulfate slag |

total |

|

|

Raw material |

82.6 |

6.3 |

5.5 |

5.6 |

100 |

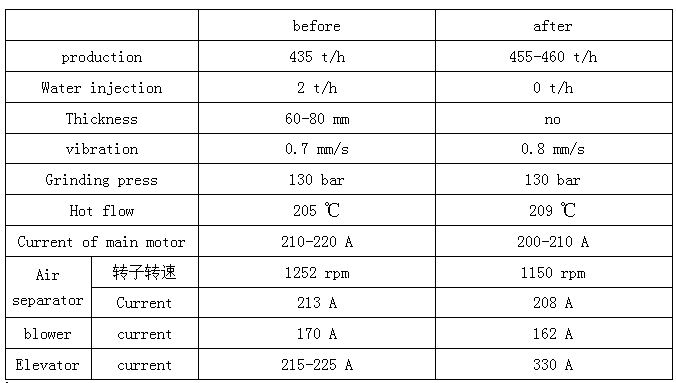

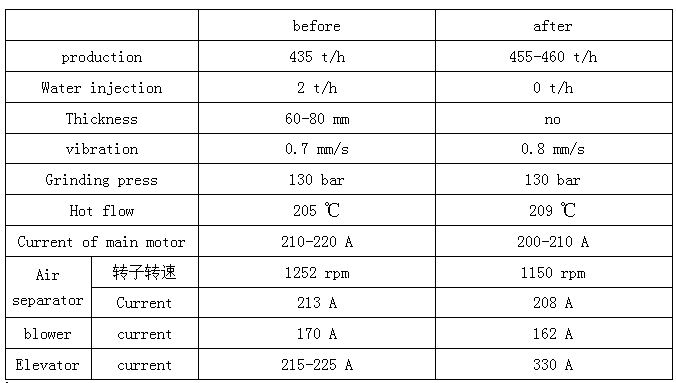

2, The running status before replacement

|

water injection capacity |

2 |

t/h |

|

|

thickness of material layer |

60-80 |

mm |

|

|

ratio of vibration |

0.7 |

mm/s |

|

|

pressure of grinding |

13 |

MPa |

|

|

temper of wind |

205 |

℃ |

|

|

current of main motor |

210-220 |

A |

|

|

air separator |

speed of rotor |

1252 |

rpm |

|

operation current |

213 |

A |

|

|

hot fan |

operation current |

170 |

A |

|

elevator |

operation current |

215-225 |

A |

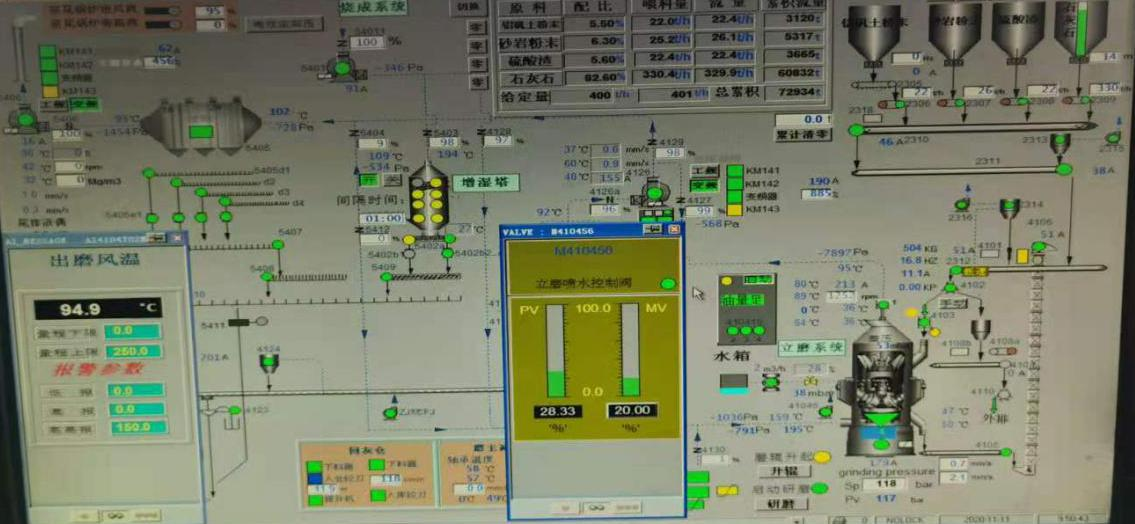

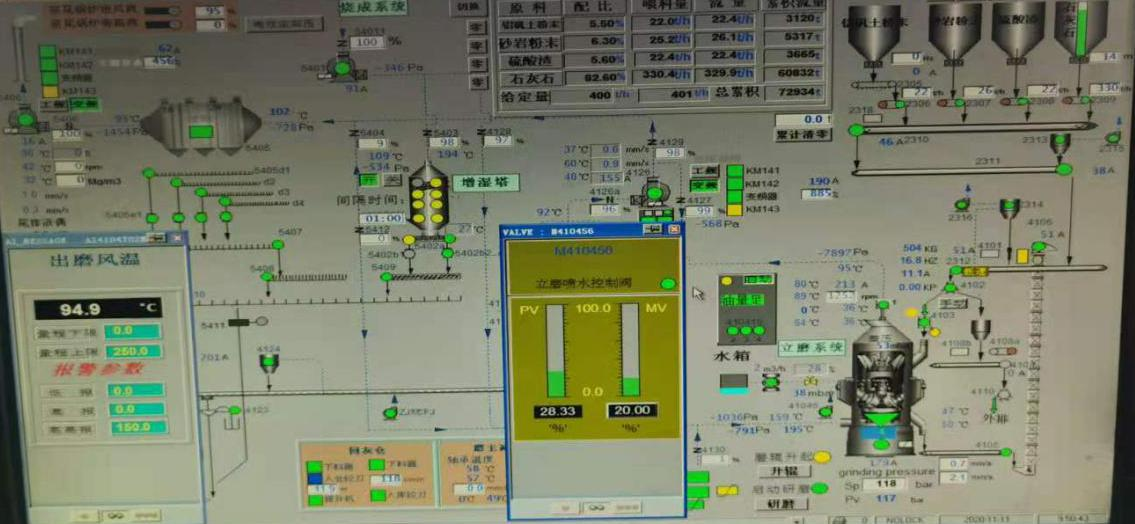

The control panel status before replacement

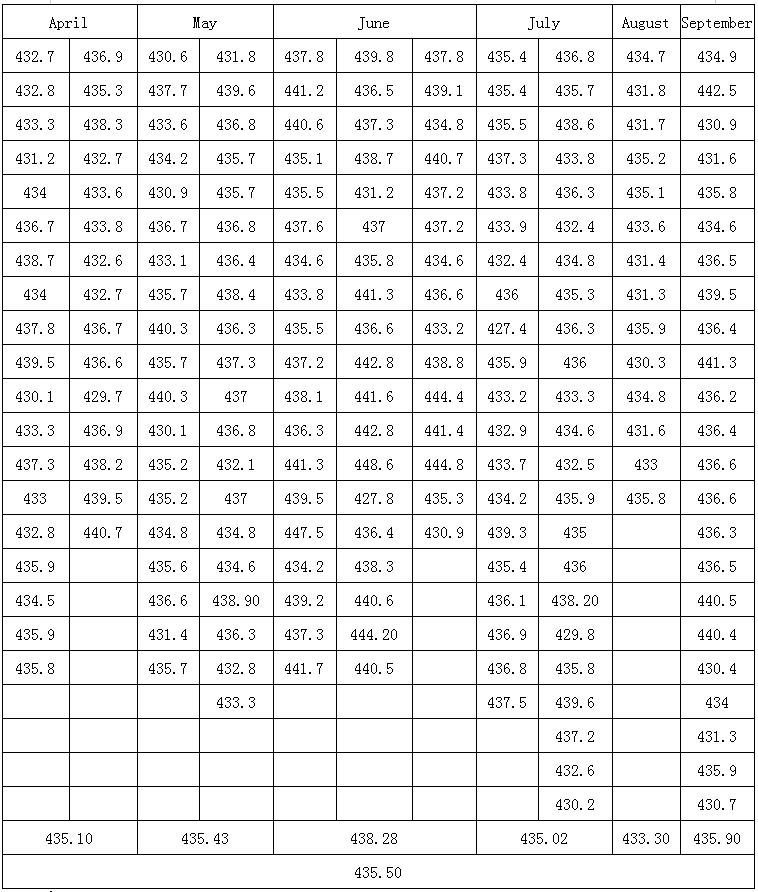

3, The production before replacement.

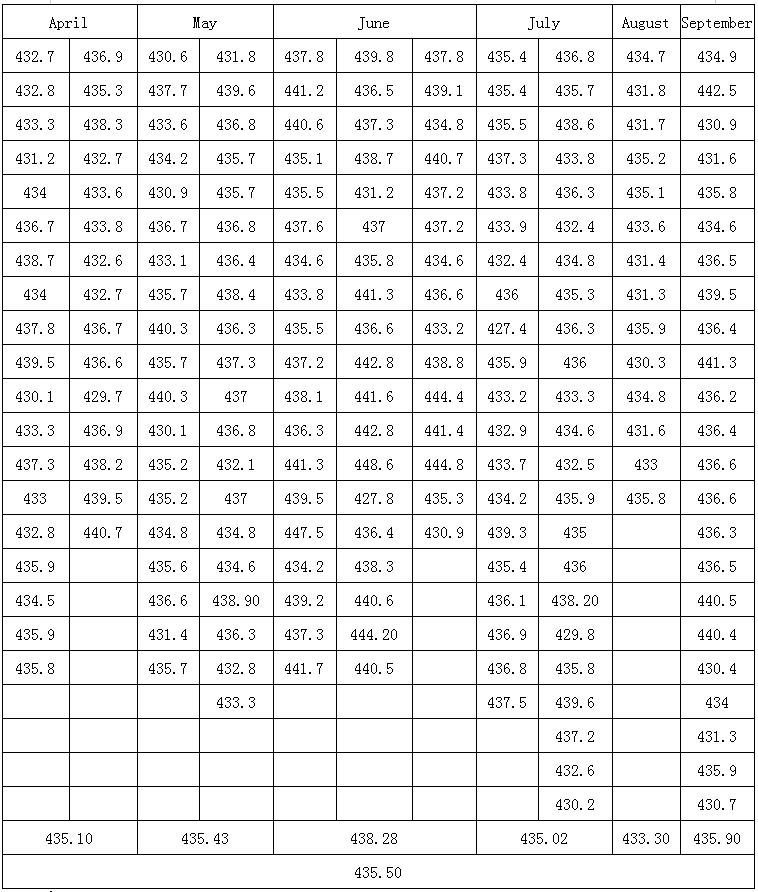

The production of April, May,June, July,August and September as below:

2, Parts replaced.

1, Replace and optimize the cone of separator to reduce the abrasive to enhance the efficiency.

2、 Change the guard vanes

3、Replace the new upgraded rotor which is optimized with different vanes and angle of flow. Meanwhile , we add the flange on the top to reduce the abrasive to improve the efficiency.

2、Change the labyrinth seal

5, The efficiency after replacement.

Based on the same working conditions, the production has been improved as 5% from 435T/H to 455-460T/H.

We replaced the rotor of ATOX50 raw mill and other related accessories which were upgraded and optimized , forced the capacity of productivity arising as 5% more and working in good condition.

1, The before status:

|

item |

Percentages |

||||

|

limestone |

Sandstone |

bauxite |

Sulfate slag |

total |

|

|

Raw material |

82.6 |

6.3 |

5.5 |

5.6 |

100 |

2, The running status before replacement

|

water injection capacity |

2 |

t/h |

|

|

thickness of material layer |

60-80 |

mm |

|

|

ratio of vibration |

0.7 |

mm/s |

|

|

pressure of grinding |

13 |

MPa |

|

|

temper of wind |

205 |

℃ |

|

|

current of main motor |

210-220 |

A |

|

|

air separator |

speed of rotor |

1252 |

rpm |

|

operation current |

213 |

A |

|

|

hot fan |

operation current |

170 |

A |

|

elevator |

operation current |

215-225 |

A |

The control panel status before replacement

3, The production before replacement.

The production of April, May,June, July,August and September as below:

2, Parts replaced.

1, Replace and optimize the cone of separator to reduce the abrasive to enhance the efficiency.

2、 Change the guard vanes

3、Replace the new upgraded rotor which is optimized with different vanes and angle of flow. Meanwhile , we add the flange on the top to reduce the abrasive to improve the efficiency.

2、Change the labyrinth seal

5, The efficiency after replacement.

Based on the same working conditions, the production has been improved as 5% from 435T/H to 455-460T/H.