ATOX50 Vertical Mill Technical Service Report 2025

Publishdate:2025-09-30 Views:108

摘要:客户一线ATOX50立磨,此次检修更换我司高铬辊皮与磨盘衬板,我司提供了安装指导服务。现场服务期间,测量了辊皮与磨盘衬板磨损数据分析等,详细情况见下文报告。

Summary: For the Line 1 ATOX50 vertical mill, high-chromium roller segments and table liner from NPM were replaced during this maintenance shutdown. NPM provided installation guidance services. During the on-site service, wear data for the roller segments and table liner were measured and analyzed. Details are provided in the report below.

一、高铬辊皮安装 High-Chromium Roller segment Installation

1、安装位置及日期 Installation Location and Date

安装位置:2#磨辊

Position: Roller 2#

安装日期:2025年9月14日-9月19日

Date: September 14, 2025 - September 19, 2025

2、安装过程及注意事项 Installation Process and Key Points

(1) 吊装前清理干净辊皮安装面防锈脂。

(1) Clean the anti-rust grease from the roller segment mounting surface before hoisting.

(2) 使用手持百叶片磨光机多次清理轮毂表面(此轮毂使用辊皮由30°辊皮改为45°辊皮)。

(2) Repeatedly clean the hub surface using a hand-held flap disc grinder (The roller segments used on this hub were changed from 30° to 45° profile).

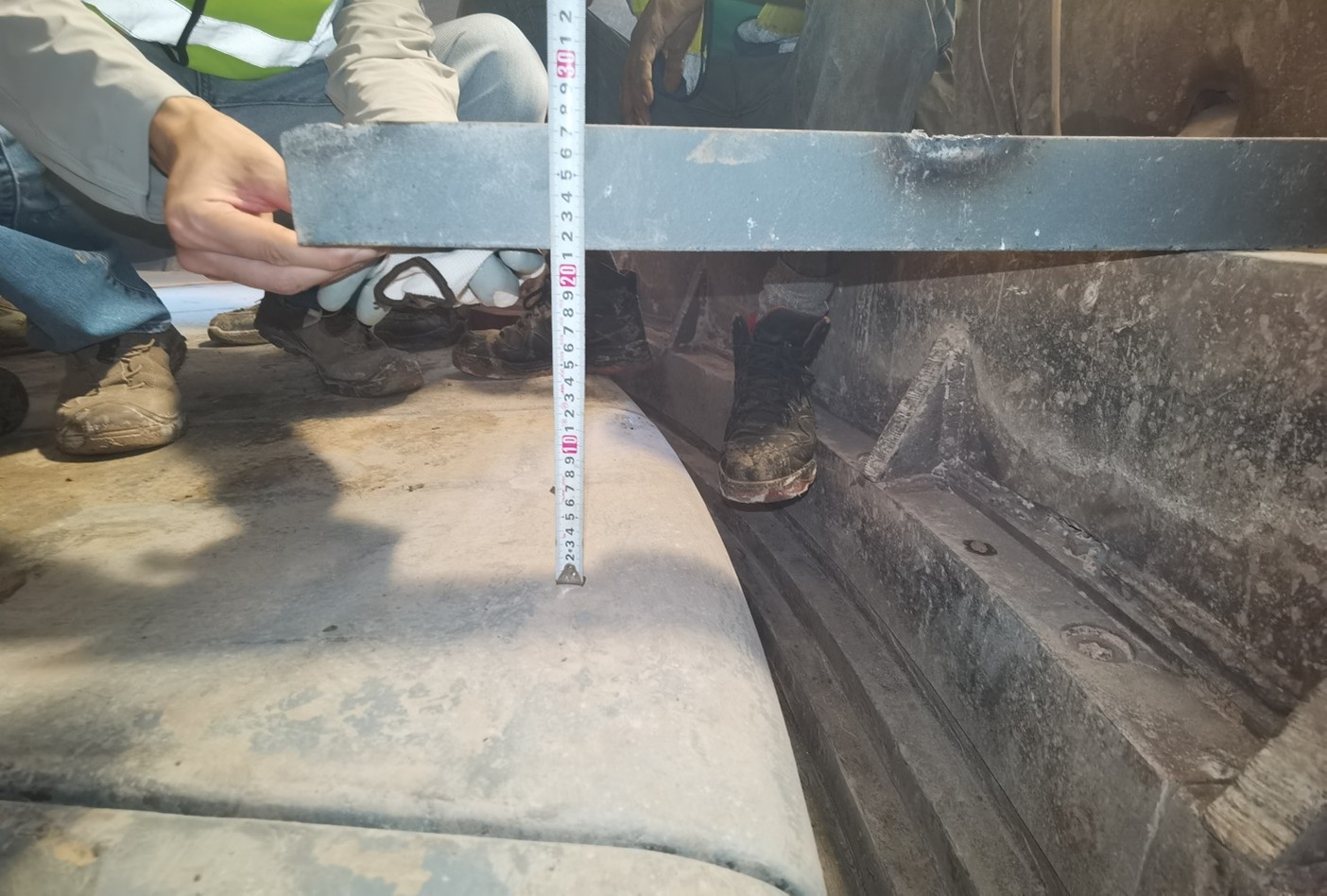

(3) 放置辊皮到正确位置后,测量辊皮与轮毂间隙超过0.15mm,因此全部辊皮安装使用了高分子金属修复剂进行填充。

(3) After placing the roller segment in the correct position, the measured gap between the segment and the hub exceeded 0.15mm. Therefore, a polymer metal repair agent was used for filling during the installation of all segments.

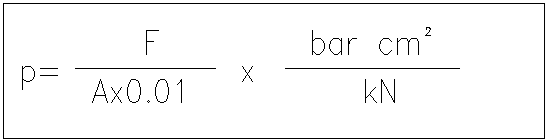

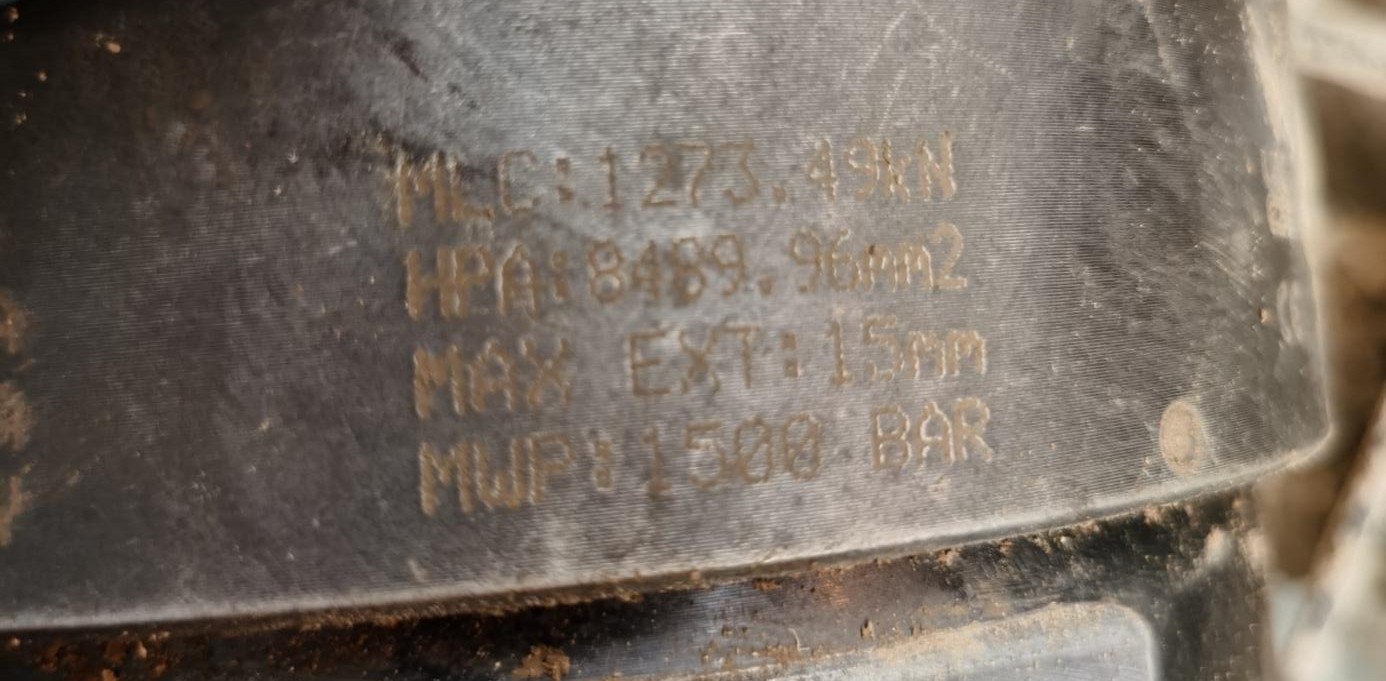

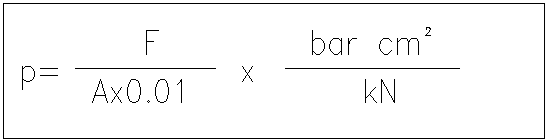

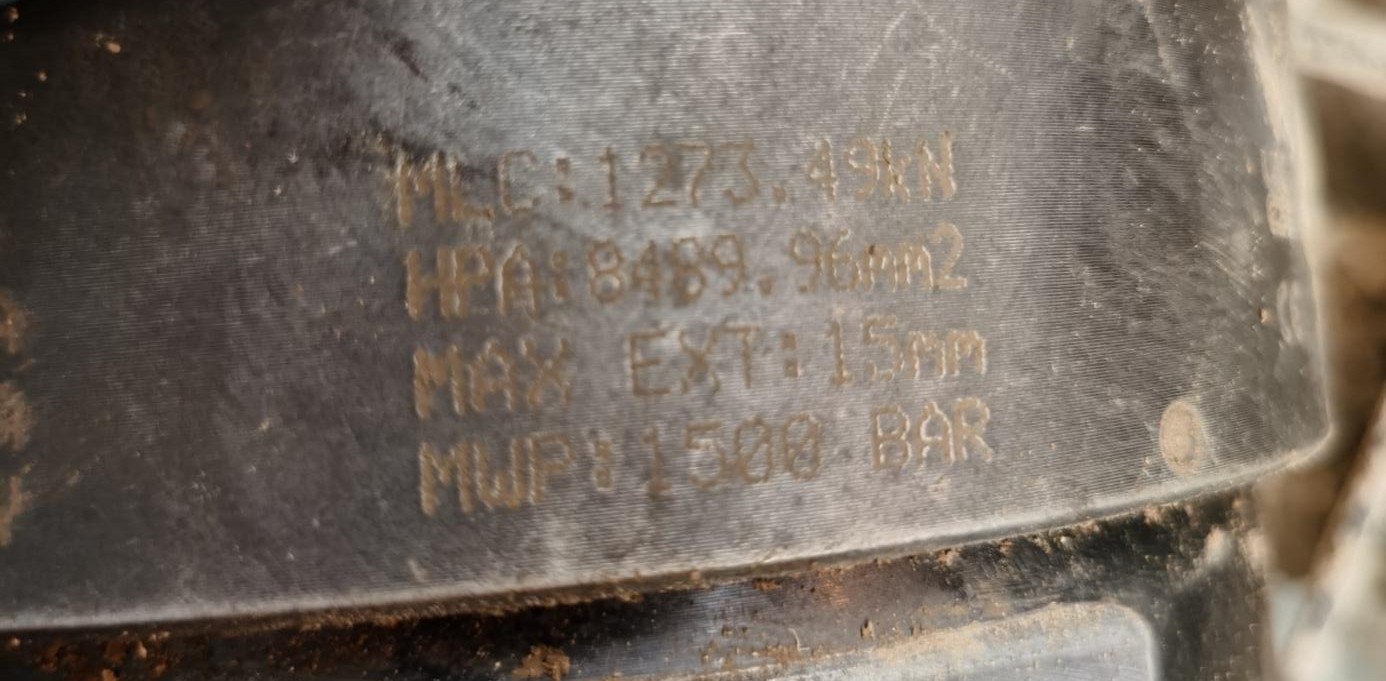

(4) 根据OEM要求,螺栓紧固Tightening force是987KN。现场工具是tentec液压螺母,根据液压螺母面积换算手动泵压力1162bar。

(4) According to OEM requirements, the bolt tightening force is 987 KN. The on-site tool used was a Tentec hydraulic nut. Based on the hydraulic nut area, the corresponding manual pump pressure was calculated to be 1162 bar.

(5) 注意事项——辊皮螺栓复紧

(5) Key Point ------ Roller segment Bolt Re-tightening

Re-Tightening of the bolts are to be carried out after 8 hours, 24 hours and after 48 hours of mill operation subsequently until the bolts torque were found to be constant.

二、磨盘衬板安装 Table Liner Installation

1、安装日期 Installation Date

2025年9月18日-9月23日

September 18, 2025 - September 23, 2025

2、安装过程及注意事项 Installation Process and Key Points

(1) 吊装前,清理干净磨盘衬板安装面防锈脂。

(1) Clean the anti-rust grease from the table liner mounting surface before hoisting.

(2) 使用手持百叶片磨光机反复打磨干净磨盘。

(2) Repeatedly grind and clean the grinding table surface using a hand-held flap disc grinder.

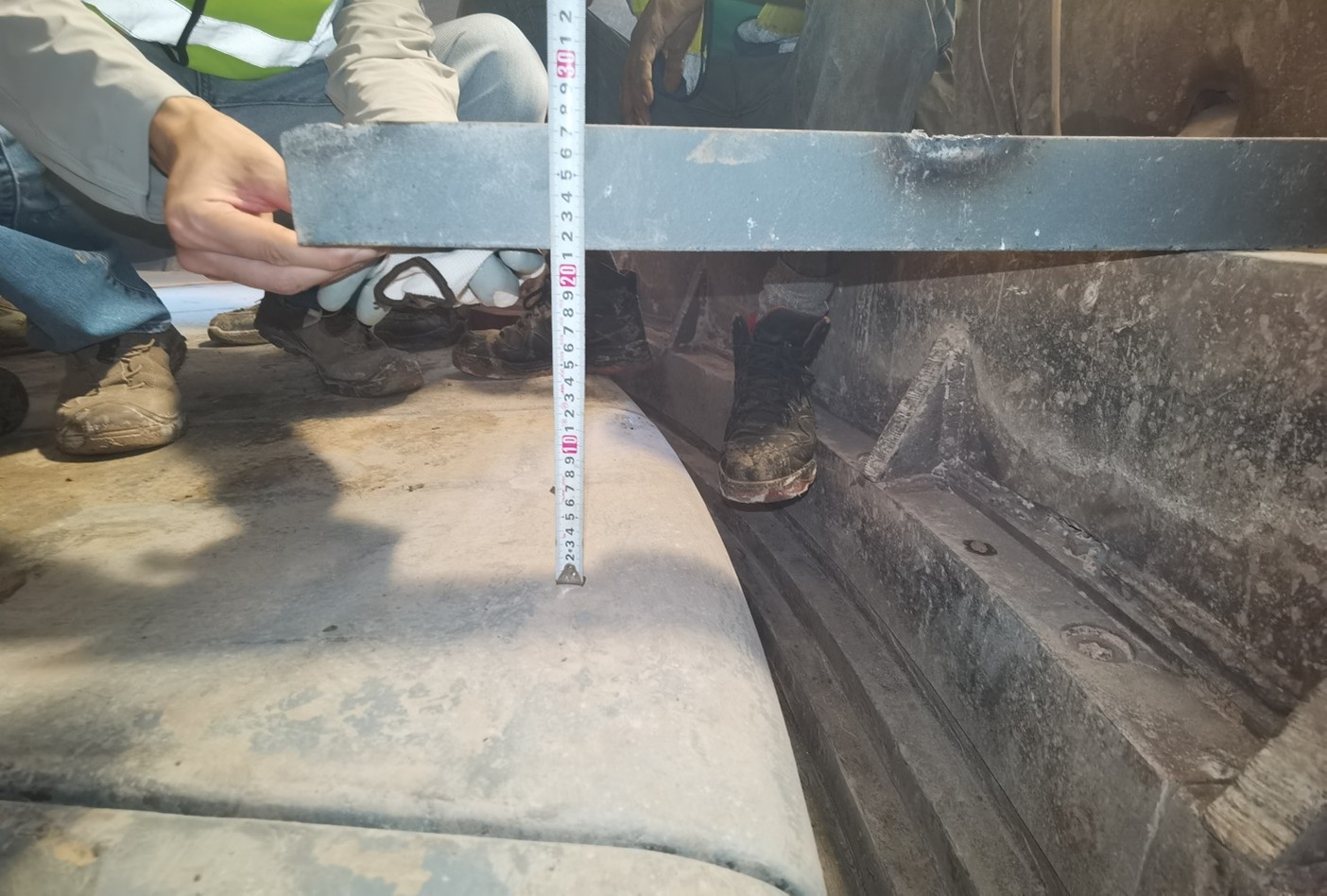

(3) 使用塞尺检查磨盘衬板与磨盘间隙符合要求。

(3) Use a feeler gauge to check the gap between the table liner segments and the table; ensure it meets requirements.

(4) 此次拆卸磨盘衬板时发现固定螺栓断裂较多,因此为了限制磨盘衬板位置,防止磨盘衬板在使用过程中出现横向移动,内外侧全部使用垫片塞紧。

(4) During the removal of the table liner, a significant number of broken fixing bolts were found. Therefore, to restrict the position of the liner segments and prevent lateral movement during operation, shims were used to tightly pack both the inner and outer sides.

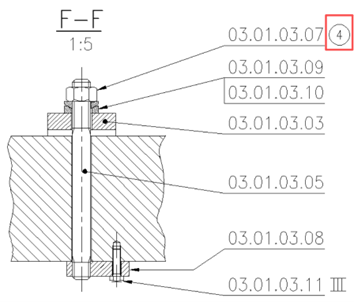

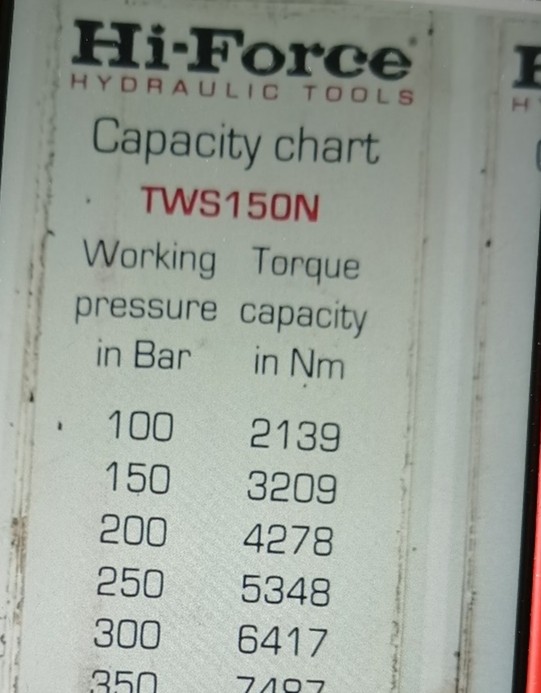

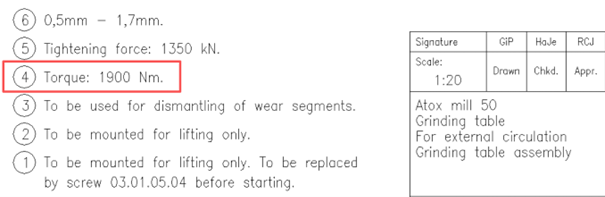

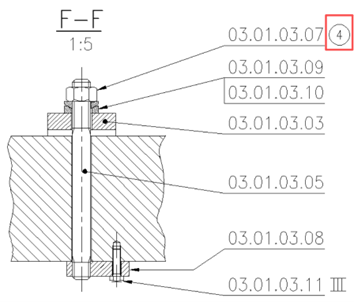

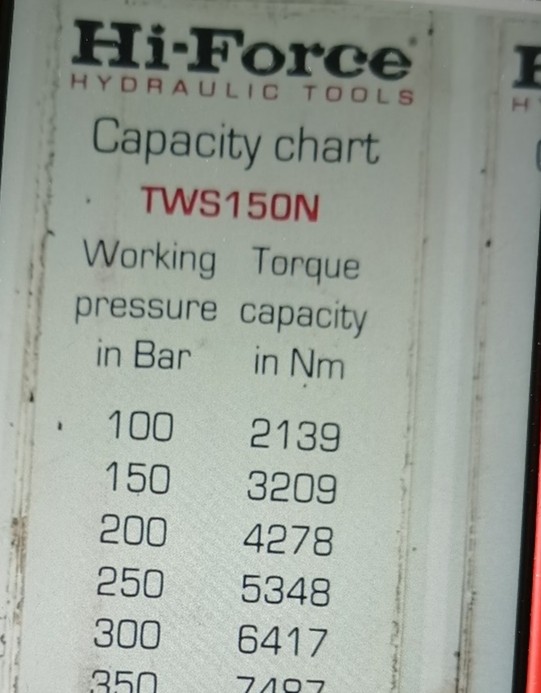

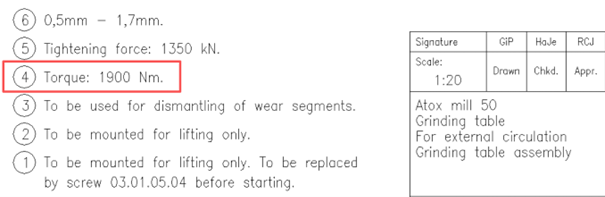

(5) 根据OEM要求,磨盘衬板螺栓紧固扭矩为1900Nm。现场使用工具是液压扭矩扳手(TWS150N),对应的要求扭矩的泵压力为90bar。

(5) According to OEM requirements, the tightening torque for the table liner bolts is 1900 Nm. Hydraulic torque wrench (TWS150N) was used on site, with a corresponding pump pressure of 90 bar for the required torque.

(6) 注意事项——磨盘衬板螺栓复紧

(6) Key Point ------ Table Liner Bolt Re-tightening

Re-Tightening of the bolts are to be carried out after 8 hours, 24 hours and after 48 hours of mill operation subsequently until the bolts torque were found to be constant.

3、挡料圈实际高度 Actual Dam Ring Height

更换新磨盘衬板后,挡料圈实际高度(从磨盘衬板表面到挡料圈顶部距离)215mm,在合理范围内,开机前不需要重新调整挡料圈高度。

After installing the new table liner segments, the actual dam ring height (distance from the table liner surface to the top of the dam ring) is 215mm, which is within the reasonable range. No adjustment of the dam ring height is required before start-up.

开机后根据磨机吐渣量、料层及主电机电流波动情况以及工艺控制要求,可适当微调挡料圈高度。

After start-up, the dam ring height can be fine-tuned appropriately based on the mill spillage, material bed thickness, fluctuations in the main motor current, and process control requirements.

三、辊皮与磨盘衬板磨损检查 Roller Segment and Table Liner Wear Inspection

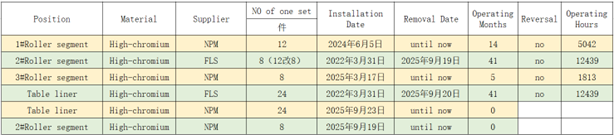

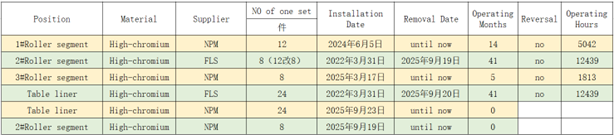

1、辊皮与磨盘衬板使用情况统计 Usage Statistics for Roller segments and Table Liner

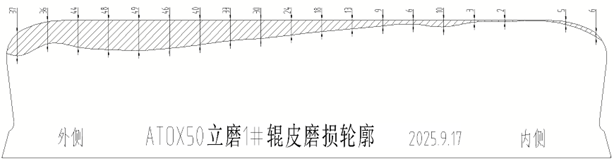

2、辊皮与磨盘衬板磨损数据、磨损轮廓 Wear Data and Wear Profiles for Roller segments and Table Liner

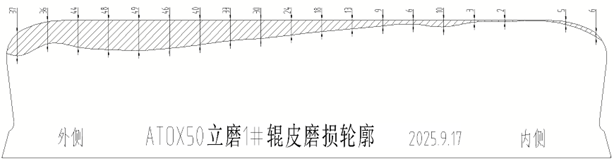

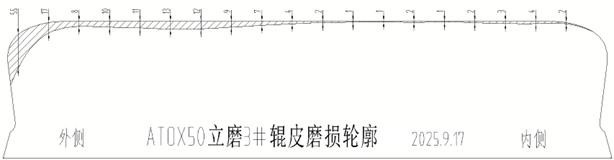

Roller 1#

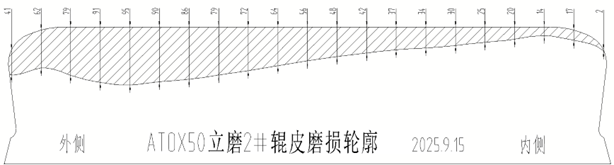

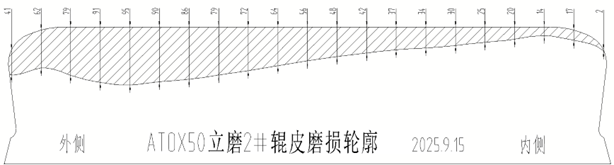

Roller 2#

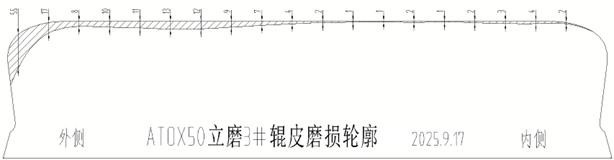

Roller 3#

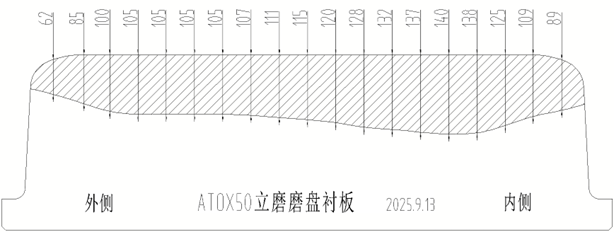

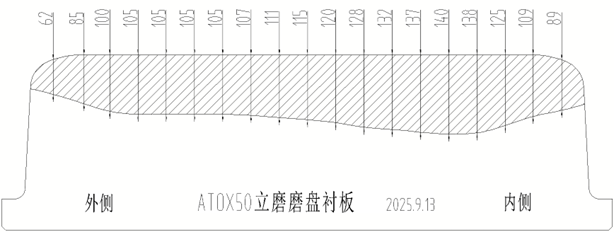

Table liner

3、结论与建议 Conclusions and Recommendations

(1) 从磨损轮廓上看,即使2#磨辊更换了新辊皮,但三个磨辊辊皮磨损程度还是存在一定差异。这样在磨机运行过程中容易造成料层不稳,磨机振动偏大从而引起其他设备故障(如磨辊轴承损坏、竖直拉杆断裂等)。

(1) Based on the wear profiles, even though a new roller segment was installed on Grinding Roller 2#, there is still a certain degree of difference in the wear levels of the three roller segments. This can easily lead to an unstable material bed during mill operation, causing increased mill vibration, which may lead to other equipment failures (such as roller bearing damage, vertical tie rod fracture, etc.).

(2) 石灰石粒度偏大,这样不仅降低粉磨效率、增加电耗,而且还会加快辊皮与磨盘衬板磨损速度、引起磨机振动。建议控制石灰石粒度在合理范围内(最大粒度不超过100mm,≤50mm粒度占比不低于85%)。

(2) The limestone particle size is relatively large. This not only reduces grinding efficiency and increases power consumption but also accelerates the wear rate of the roller segments and table liner, and can cause mill vibration. It is recommended to control the limestone particle size within a reasonable range (maximum particle size not exceeding 100mm, proportion of particles ≤50mm should be no less than 85%).

(3) 建议明年大修期间更换1#磨辊辊皮,同时根据2#、3#辊皮磨损情况进行调面,这样降低三个磨辊辊皮磨损差异程度。

(3) It is recommended to replace the roller segment on Grinding Roller 1# during next year’s overhaul. Simultaneously, reverse Roller 2# and 3# segments based on the wear condition. This will help reduce the disparity in wear among the three roller segments.

(4) 建议后续三个磨辊辊皮同步进行更换,这样在辊皮磨损差异相近的情况下,可以使得磨机运行更加稳定。

(4) It is recommended to replace the roller segments on all three grinding rollers at the same time in the future. This will allow the mill to operate more stably when the three roller segments have similar wear level.

(5) 建议控制磨盘衬板最大磨损量(不超过70mm),有利于使得磨机保持较高的粉磨效率。

(5) It is recommended to control the maximum wear amount of the table liner (not exceeding 70mm), which is beneficial for maintaining high grinding efficiency of the mill.

摘要:客户一线ATOX50立磨,此次检修更换我司高铬辊皮与磨盘衬板,我司提供了安装指导服务。现场服务期间,测量了辊皮与磨盘衬板磨损数据分析等,详细情况见下文报告。

Summary: For the Line 1 ATOX50 vertical mill, high-chromium roller segments and table liner from NPM were replaced during this maintenance shutdown. NPM provided installation guidance services. During the on-site service, wear data for the roller segments and table liner were measured and analyzed. Details are provided in the report below.

一、高铬辊皮安装 High-Chromium Roller segment Installation

1、安装位置及日期 Installation Location and Date

安装位置:2#磨辊

Position: Roller 2#

安装日期:2025年9月14日-9月19日

Date: September 14, 2025 - September 19, 2025

2、安装过程及注意事项 Installation Process and Key Points

(1) 吊装前清理干净辊皮安装面防锈脂。

(1) Clean the anti-rust grease from the roller segment mounting surface before hoisting.

(2) 使用手持百叶片磨光机多次清理轮毂表面(此轮毂使用辊皮由30°辊皮改为45°辊皮)。

(2) Repeatedly clean the hub surface using a hand-held flap disc grinder (The roller segments used on this hub were changed from 30° to 45° profile).

(3) 放置辊皮到正确位置后,测量辊皮与轮毂间隙超过0.15mm,因此全部辊皮安装使用了高分子金属修复剂进行填充。

(3) After placing the roller segment in the correct position, the measured gap between the segment and the hub exceeded 0.15mm. Therefore, a polymer metal repair agent was used for filling during the installation of all segments.

(4) 根据OEM要求,螺栓紧固Tightening force是987KN。现场工具是tentec液压螺母,根据液压螺母面积换算手动泵压力1162bar。

(4) According to OEM requirements, the bolt tightening force is 987 KN. The on-site tool used was a Tentec hydraulic nut. Based on the hydraulic nut area, the corresponding manual pump pressure was calculated to be 1162 bar.

(5) 注意事项——辊皮螺栓复紧

(5) Key Point ------ Roller segment Bolt Re-tightening

Re-Tightening of the bolts are to be carried out after 8 hours, 24 hours and after 48 hours of mill operation subsequently until the bolts torque were found to be constant.

二、磨盘衬板安装 Table Liner Installation

1、安装日期 Installation Date

2025年9月18日-9月23日

September 18, 2025 - September 23, 2025

2、安装过程及注意事项 Installation Process and Key Points

(1) 吊装前,清理干净磨盘衬板安装面防锈脂。

(1) Clean the anti-rust grease from the table liner mounting surface before hoisting.

(2) 使用手持百叶片磨光机反复打磨干净磨盘。

(2) Repeatedly grind and clean the grinding table surface using a hand-held flap disc grinder.

(3) 使用塞尺检查磨盘衬板与磨盘间隙符合要求。

(3) Use a feeler gauge to check the gap between the table liner segments and the table; ensure it meets requirements.

(4) 此次拆卸磨盘衬板时发现固定螺栓断裂较多,因此为了限制磨盘衬板位置,防止磨盘衬板在使用过程中出现横向移动,内外侧全部使用垫片塞紧。

(4) During the removal of the table liner, a significant number of broken fixing bolts were found. Therefore, to restrict the position of the liner segments and prevent lateral movement during operation, shims were used to tightly pack both the inner and outer sides.

(5) 根据OEM要求,磨盘衬板螺栓紧固扭矩为1900Nm。现场使用工具是液压扭矩扳手(TWS150N),对应的要求扭矩的泵压力为90bar。

(5) According to OEM requirements, the tightening torque for the table liner bolts is 1900 Nm. Hydraulic torque wrench (TWS150N) was used on site, with a corresponding pump pressure of 90 bar for the required torque.

(6) 注意事项——磨盘衬板螺栓复紧

(6) Key Point ------ Table Liner Bolt Re-tightening

Re-Tightening of the bolts are to be carried out after 8 hours, 24 hours and after 48 hours of mill operation subsequently until the bolts torque were found to be constant.

3、挡料圈实际高度 Actual Dam Ring Height

更换新磨盘衬板后,挡料圈实际高度(从磨盘衬板表面到挡料圈顶部距离)215mm,在合理范围内,开机前不需要重新调整挡料圈高度。

After installing the new table liner segments, the actual dam ring height (distance from the table liner surface to the top of the dam ring) is 215mm, which is within the reasonable range. No adjustment of the dam ring height is required before start-up.

开机后根据磨机吐渣量、料层及主电机电流波动情况以及工艺控制要求,可适当微调挡料圈高度。

After start-up, the dam ring height can be fine-tuned appropriately based on the mill spillage, material bed thickness, fluctuations in the main motor current, and process control requirements.

三、辊皮与磨盘衬板磨损检查 Roller Segment and Table Liner Wear Inspection

1、辊皮与磨盘衬板使用情况统计 Usage Statistics for Roller segments and Table Liner

2、辊皮与磨盘衬板磨损数据、磨损轮廓 Wear Data and Wear Profiles for Roller segments and Table Liner

Roller 1#

Roller 2#

Roller 3#

Table liner

3、结论与建议 Conclusions and Recommendations

(1) 从磨损轮廓上看,即使2#磨辊更换了新辊皮,但三个磨辊辊皮磨损程度还是存在一定差异。这样在磨机运行过程中容易造成料层不稳,磨机振动偏大从而引起其他设备故障(如磨辊轴承损坏、竖直拉杆断裂等)。

(1) Based on the wear profiles, even though a new roller segment was installed on Grinding Roller 2#, there is still a certain degree of difference in the wear levels of the three roller segments. This can easily lead to an unstable material bed during mill operation, causing increased mill vibration, which may lead to other equipment failures (such as roller bearing damage, vertical tie rod fracture, etc.).

(2) 石灰石粒度偏大,这样不仅降低粉磨效率、增加电耗,而且还会加快辊皮与磨盘衬板磨损速度、引起磨机振动。建议控制石灰石粒度在合理范围内(最大粒度不超过100mm,≤50mm粒度占比不低于85%)。

(2) The limestone particle size is relatively large. This not only reduces grinding efficiency and increases power consumption but also accelerates the wear rate of the roller segments and table liner, and can cause mill vibration. It is recommended to control the limestone particle size within a reasonable range (maximum particle size not exceeding 100mm, proportion of particles ≤50mm should be no less than 85%).

(3) 建议明年大修期间更换1#磨辊辊皮,同时根据2#、3#辊皮磨损情况进行调面,这样降低三个磨辊辊皮磨损差异程度。

(3) It is recommended to replace the roller segment on Grinding Roller 1# during next year’s overhaul. Simultaneously, reverse Roller 2# and 3# segments based on the wear condition. This will help reduce the disparity in wear among the three roller segments.

(4) 建议后续三个磨辊辊皮同步进行更换,这样在辊皮磨损差异相近的情况下,可以使得磨机运行更加稳定。

(4) It is recommended to replace the roller segments on all three grinding rollers at the same time in the future. This will allow the mill to operate more stably when the three roller segments have similar wear level.

(5) 建议控制磨盘衬板最大磨损量(不超过70mm),有利于使得磨机保持较高的粉磨效率。

(5) It is recommended to control the maximum wear amount of the table liner (not exceeding 70mm), which is beneficial for maintaining high grinding efficiency of the mill.